Pouch processing was successful with the use of ECOPEX (BOPE) produced by JK Materials BOPE line.

It can be a barrier of oxygen and water from lamination with high barrier co-extrusion film.

Therefore, it develops more improved barrier properties from existing BOPE film.

It is expected to expand its purpose by manufacturing envelopes such as square pouches and 2 Side seal pouches, which are difficult to process with the standard polyethylene to make pet food and coffee pouches.

Please refer to the photos, film, laminate and high barrier co-extrusion PE report of the pouch made from ECOPEX (BOPE film).

Photo 1. A square pouch processed from BOPE/LLDPE film on the left, a 2 Side seal pouch processed with BOPE/High barrier co-extruded LLDPE film on the right

Photo 2. A square pouch processed from BOPE/LLDPE film (liquid is filled)

Photo 2. A square pouch processed from BOPE/LLDPE film (liquid is filled)

Photo 3. A 2 Side seal pouch processed from BOPE/High barrier co-extruded LLDPE film

Photo 3. A 2 Side seal pouch processed from BOPE/High barrier co-extruded LLDPE film

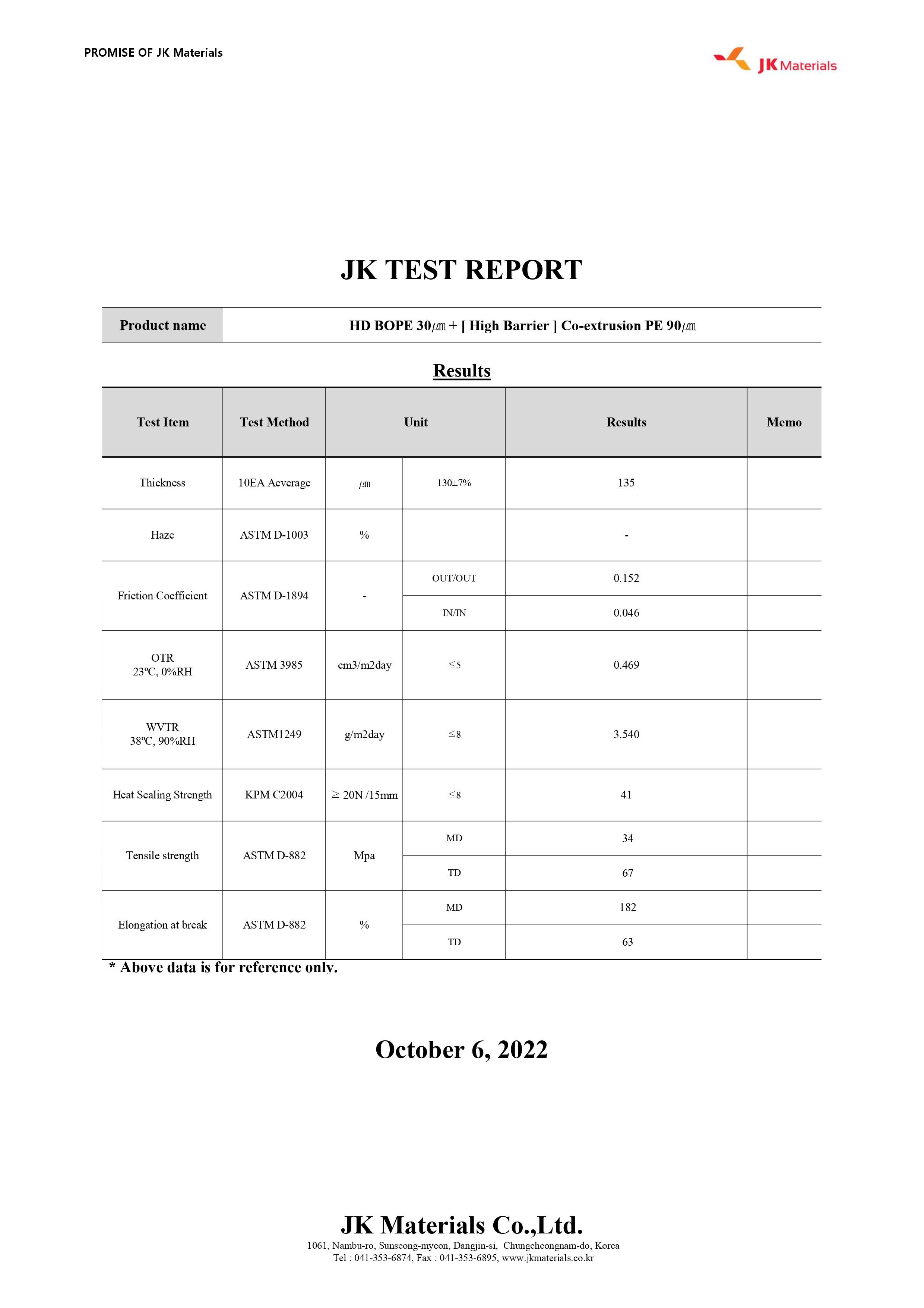

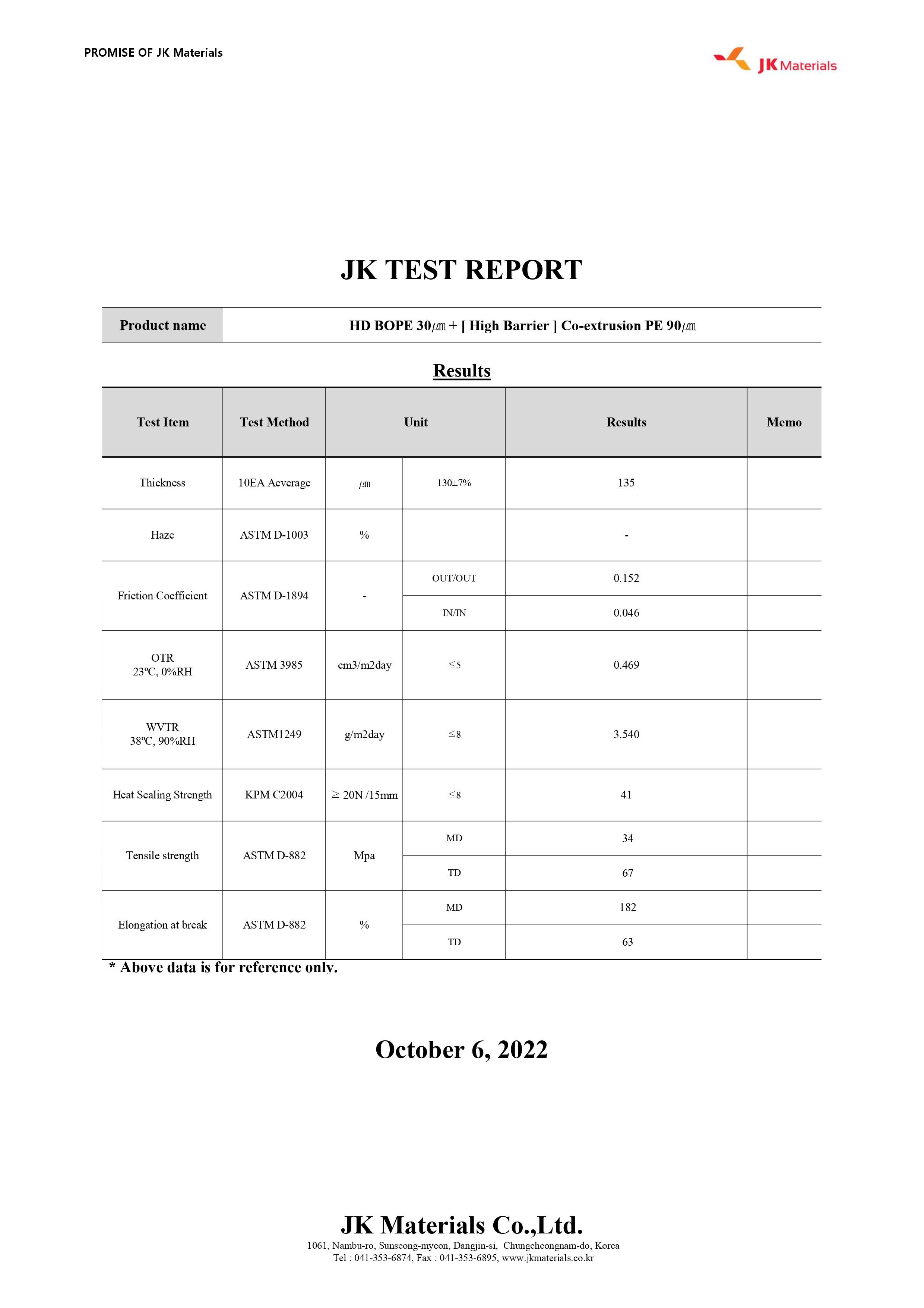

Certificate 1. TDS of BOPE30㎛/High barrier co-extruded LLDPE 90㎛ film laminate

Certificate 1. TDS of BOPE30㎛/High barrier co-extruded LLDPE 90㎛ film laminate

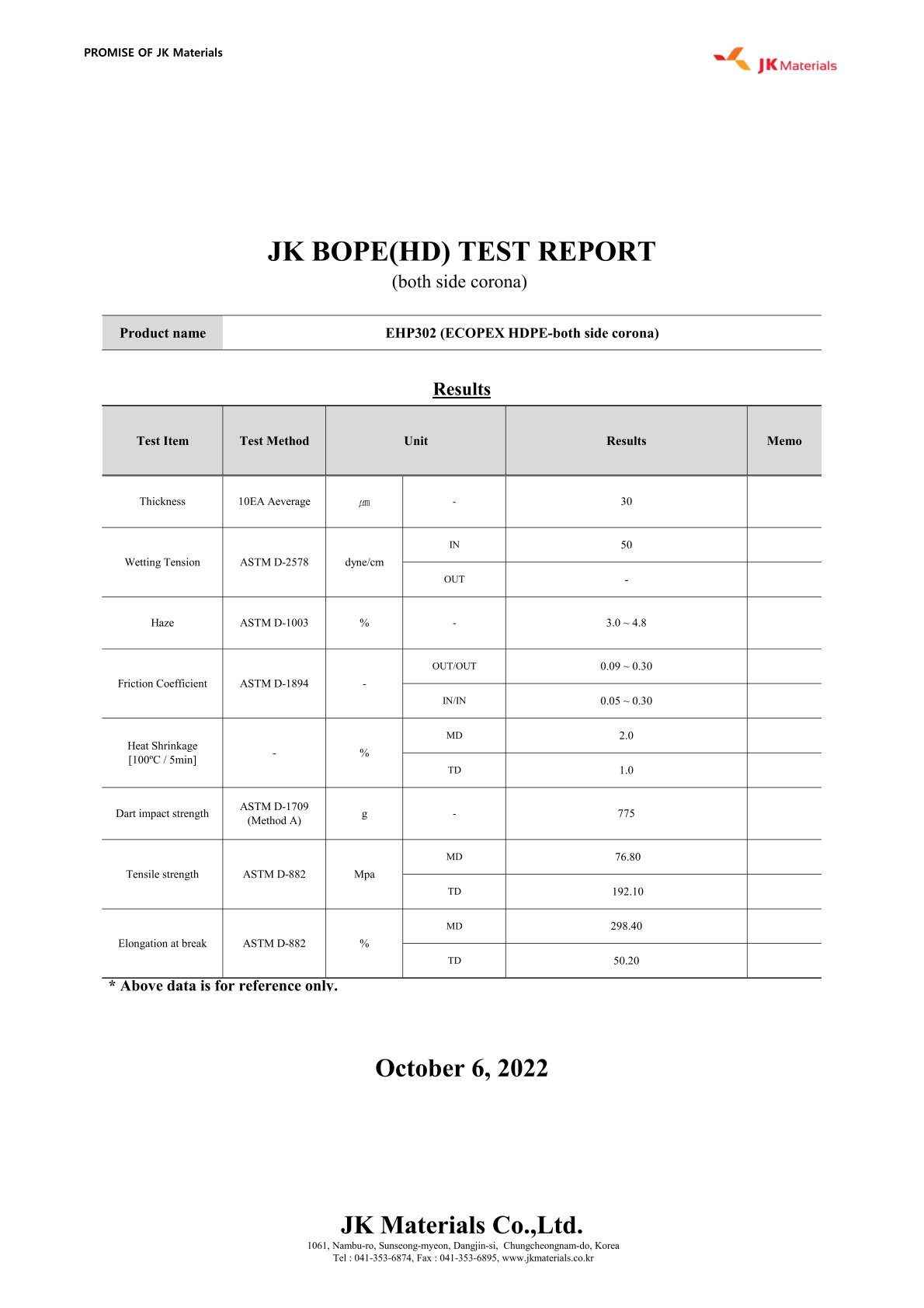

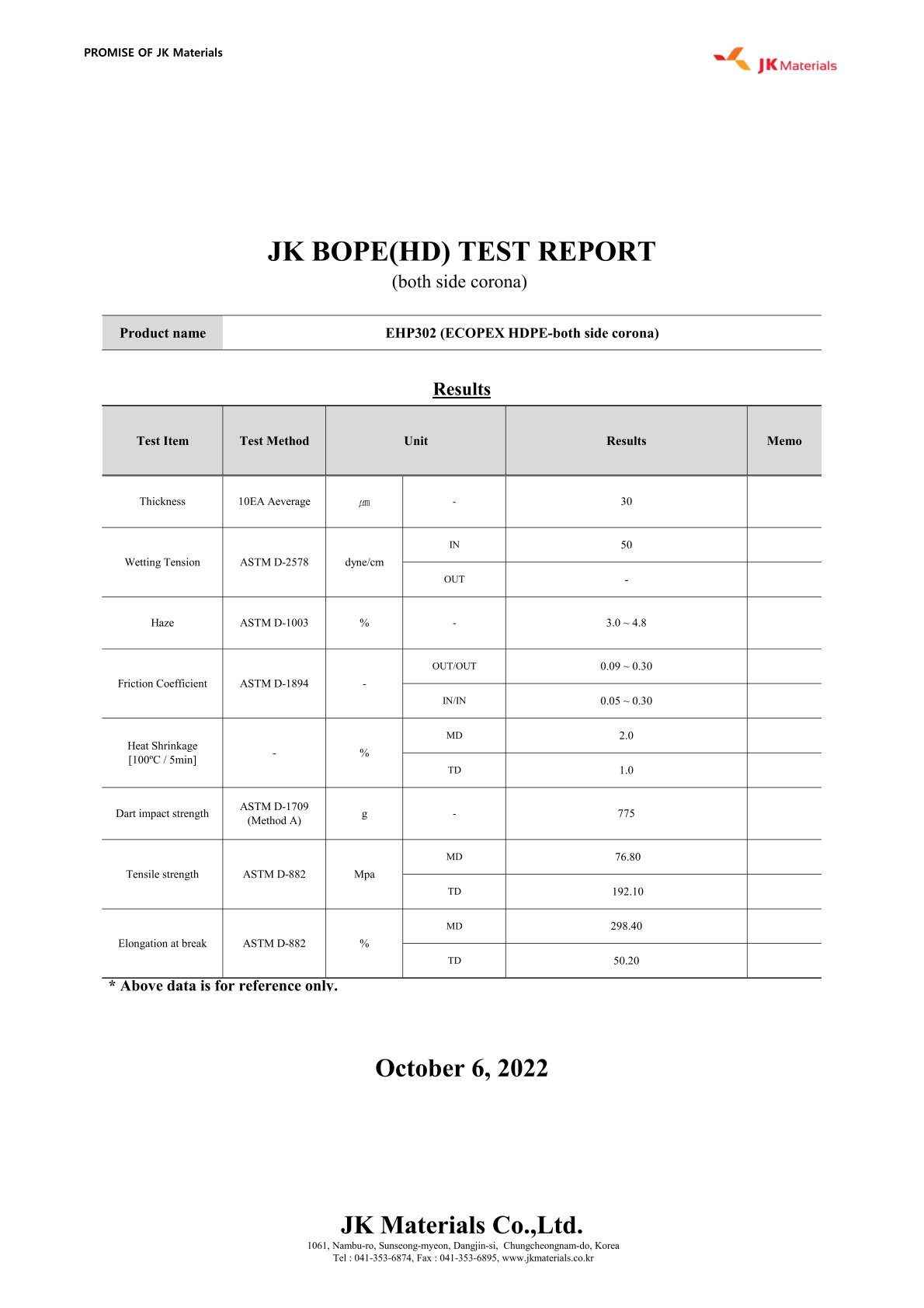

Certificate 2. TDS of ECOPEX (HDPE) 30㎛

Certificate 2. TDS of ECOPEX (HDPE) 30㎛

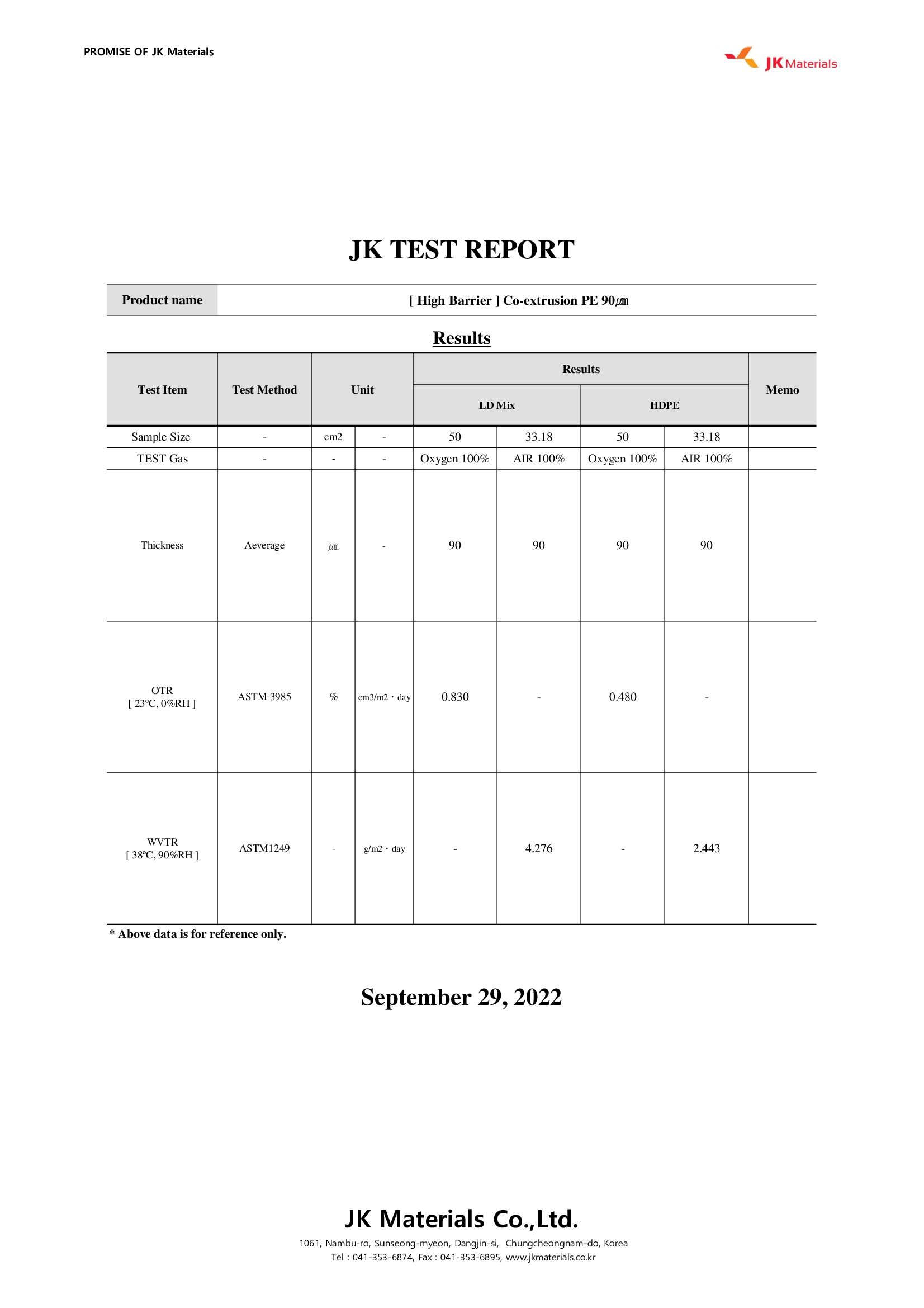

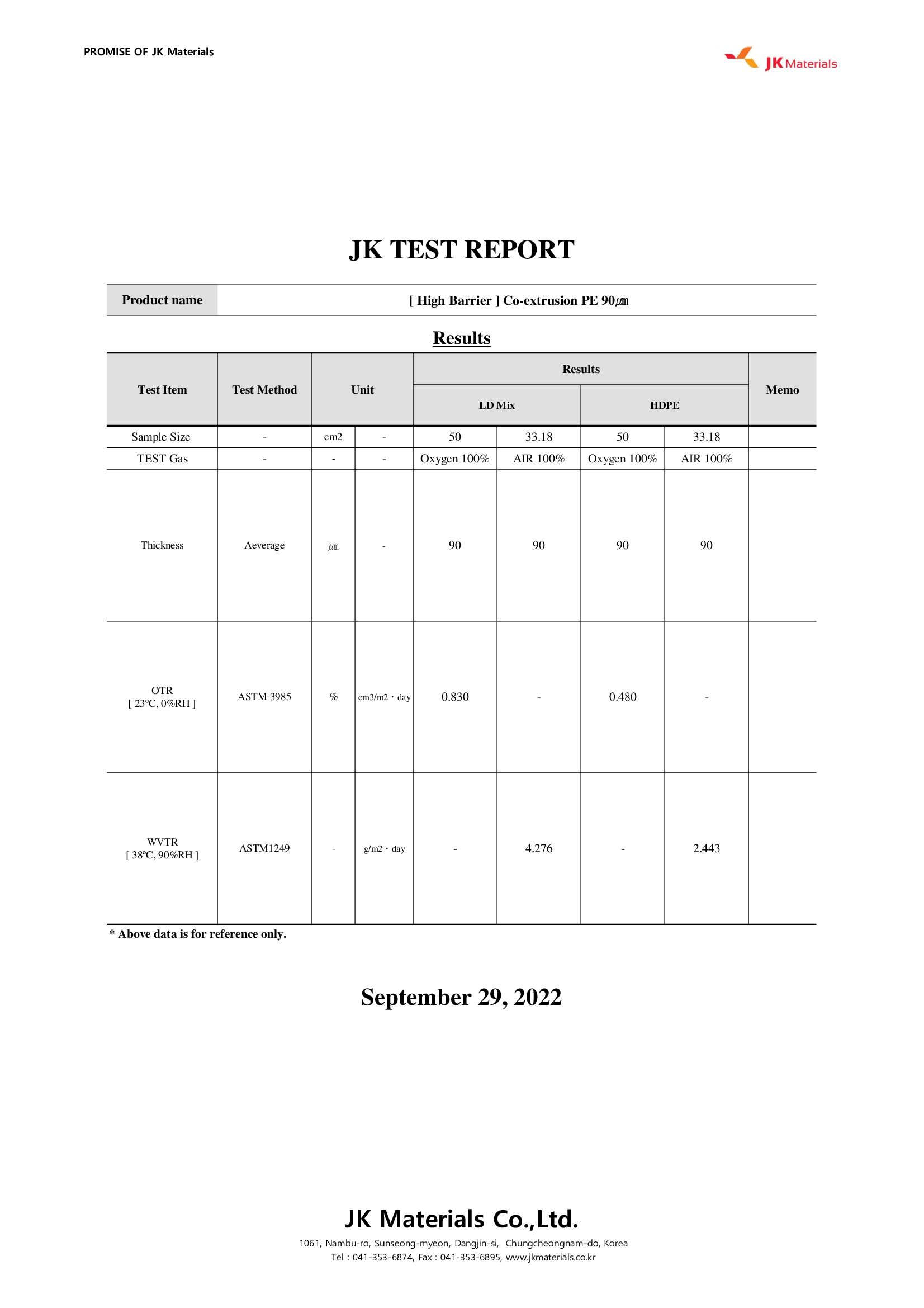

Certificate 3. TDS of High barrier co-extruded LLDPE film 90㎛ OTR, WVTR

Certificate 3. TDS of High barrier co-extruded LLDPE film 90㎛ OTR, WVTR

Certificate 3. TDS of High barrier co-extruded LLDPE film 90㎛ OTR, WVTR

Certificate 3. TDS of High barrier co-extruded LLDPE film 90㎛ OTR, WVTR